Ukukhetha ilungeloimishini yokugaya imihlathiidlala indima ebalulekile ekusebenzeni kahle. Le mishini ibalulekile ezimbonini ezifana nezimayini nezokwakha, lapho isebenza khonaukuthuthukisa ukukhiqiza ngokudiliza izinto ezinkulu. Izici ezibalulekile, njengobuchwepheshe obuthuthukisiwe namapharamitha wokuklama, zithinta kakhulu ukusebenza nokuthembeka. Isibonelo, imishini enamadrayivu asebenzisa amanzi kanye namaphaneli okulawula asebenziseka kalula ingakhuphula ukuphuma futhi inciphise isikhathi sokuphumula. Ngaphezu kwalokho, ukuqonda okuhlukahlukeneizingxenye zomhlathi we-crusher, kuhlanganiseizingxenye zokugqoka ze-jaw crusher, ibalulekile ekunakekeleni nasekuphileni isikhathi eside. Ukwehluka phakathi kwemikhiqizo namamodeli, njengosayizi wokuphakelayo nokuhamba, kuphinde kube nomthelela ekusebenzeni kwemishini yokugaya imihlathi, kuyilapho kubhekwa nokubalulekaizingxenye ze-rock crusherfuthiizingxenye ezisele ze-cone crusherimpumelelo yokusebenza iyonke.

Okuthathwayo Okubalulekile

- Ukukhetha i-crusher yomhlathi elungilekuthuthukisa ukusebenza kahle. Gxila ezicini ezifana nomthamo wokuchoboza nokuphatheka ukuze uhlangabezane nezidingo zakho ezithile.

- Izinto ezisezingeni eliphezulu, njengehigh manganese steel, thuthukisa ukuqina nokuphila. Khetha imishini eyakhiwe ngezinto eziqinile ukuze unciphise ukuguga.

- Ukunakekelwa okuvamile kubalulekile ekusebenzeni kahle. Hlela ukuhlolwa futhi ugcine izingxenye eziyisipele zitholakala kalula ukuze unciphise isikhathi sokuphumula kanye nezindleko zokulungisa.

- Ukuqonda umthamo wokuchoboza kanye nesilinganiso sokunciphisa kusiza ekukhetheni umshini ofanele. Qinisekisa ukuthi imodeli ifana nemigomo yakho yokukhiqiza ukuze uthole imiphumela emihle.

- Ukwesekwa ngemuva kokuthengisa, okuhlanganisa amawaranti nokuqeqeshwa, kubalulekile. Amasistimu okusekela aqinile athuthukisa inani lomshini futhi aqinisekise ukusebenza ngempumelelo.

Dizayina futhi Wakha Ikhwalithi Yemishini Yokugxoba Imihlathi

Iklama futhi wakhe ikhwalithiyemishini yokugaya imihlathi ithonya kakhulu ukusebenza kwayo nokuphila isikhathi eside. Abakhiqizi babeka phambili ukusebenzisa izinto zekhwalithi ephezulu ukuze bathuthukise ukuqina. Isibonelo, insimbi ephezulu ye-manganese inganikeza isikhathi sokuphila esinjalo30-50% ubudeuma kuqhathaniswa nezinto ezijwayelekile. Lokhu kukhethwa kwezinto akugcini nje ngokuthuthukisa ukuqina kodwa futhi kuqinisekisa ukuthi imishini ingakwazi ukumelana nobunzima bokusetshenziswa kanzima.

Izinto Ezisetshenziswayo

Abakhiqizi abaphezulu bagxila kuyoemisha ekwakhiweni komkhiqizo. Batshala imali ocwaningweni nasekuthuthukisweni ukuze bakhe ubuchwepheshe obusezingeni eliphezulu nezinto zokwakha. Lokhu kuzibophezela kuholela emishinini yokugaya imihlathi esebenza kahle futhi ethembekile. Ukuqina nokugqamuka kwezinto eziphakelayo nakho kudlala indima ebalulekile emazingeni okuguga, okunomthelela ubude besikhathi sokuphila kwezinto zokusebenza. Ukuhlola okuvamile kunganweba ingxenye yempilo kuze kufike ku-30%, kukhulise impilo yonke ngokulungiswa okumatasa.

Ubuqotho Besakhiwo

Ubuqotho besakhiwo bubalulekile empumelelweni yokusebenza kwemishini yokugaya imihlathi. Amafreyimu aqinile futhi aklanywe kahle avimbela ukuwohloka ngaphansi kwemithwalo esindayo. Le khwalithi iqinisekisa ukuthi imishini igcina ukusebenza kwayo ngokuhamba kwesikhathi. Ukusebenzisa izingxenye ezingagugi kunganciphisa ukushintshwa ngo-35%, kunciphise isikhathi sokuphumula futhi kwandise isikhathi sokusebenza. Ukusebenzisana phakathi kwamapuleti emihlathi kanye nezinhlayiya zezinto ezibonakalayo kuholela ekugugeni okuphawulekayo, okunganciphisa ukusebenza kahle futhi kwandise ukusetshenziswa kwamandla.

Izici zokuphatheka

Izici zokuphatheka zibalulekile ezimbonini eziningi. Umshini ophathwayo we-crusher emhlathini uvumela ukuhamba kalula phakathi kwezindawo zomsebenzi. Lokhu kuvumelana nezimo kungathuthukisa ukukhiqiza futhi kunciphise izindleko zokusebenza. Abakhiqizi be-Elite banikeza izinhlobonhlobo zama-crushers aklanyelwe imisebenzi ehlukahlukene, okubonisa ukuqonda kwabo ngezidingo zemakethe ezihlukahlukene. Ukwengeza, amasistimu okusekela aqinile, okuhlanganisa ukufinyelela okusheshayo kwezingxenye ezisele nokunakekelwa, kubalulekile ukuze kuncishiswe isikhathi sokuphumula.

Amamethrikhi okusebenza weMishini ye-Jaw Crusher

Amamethrikhi okusebenzadlala indima ebalulekile ekuhloleni imishini yokugaya imihlathi. Lawa mamethrikhi asiza abasebenzisi ukuthi baqonde ukuthi umshini ungenza kahle kangakanani ezinhlelweni zokusebenza ezahlukahlukene. Amamethrikhi amathathu okhiye okusebenza afaka umthamo wokuchoboza, isilinganiso sokunciphisa, nokusebenza kahle kwamandla.

Ikhono lokuchoboza

Umthamo wokuchoboza ubhekisela enanini lempahla i-crusher yomhlathi engacubungula ngesikhathi esinikeziwe. Le metric ibalulekile ekunqumeni ukufaneleka komshini emisebenzini ethile. Amamodeli ahlukene abonisa amakhono ahlukahlukene ngokusekelwe ekwakhiweni kwawo kanye nemingcele yokusebenza.

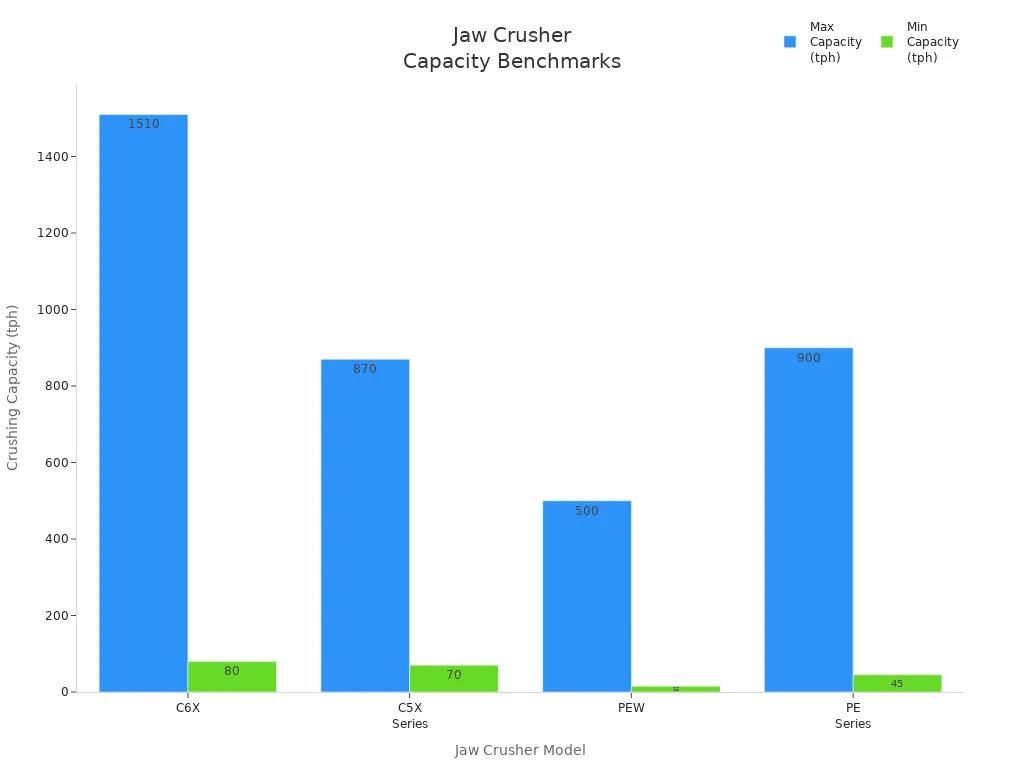

Nali ithebula elibonisa amandla okuchoboza amamodeli adumile e-jaw crusher:

| Imodeli | Usayizi Wokufaka | Amandla (tph) | Izinhlelo zokusebenza |

|---|---|---|---|

| I-C6X | 0-1280mm | 80-1510TPH | Izimayini ezinkulu, amaphrojekthi wengqalasizinda |

| Uchungechunge lwe-C5X | 0-920mm | 70-870TPH | Imisebenzi ephakathi ukuya kwezinkulu |

| I-PEW | 80-1510TPH | 15-500TPH | Izimayini ezisezingeni eliphakathi, ukukhiqizwa okuhlanganisiwe |

| Uchungechunge lwe-PE | 0-1020mm | 45-900TPH | Imisebenzi emincane kuya kwemaphakathi |

Ezininganaizici zithonya umthamo wokuchoboza, okuhlanganisa:

- Umklamo we-crusher: Amamodeli ahlukene, njengezinhlobo ze-Dodge ne-Blake, anemiklamo eyingqayizivele ethinta umthamo.

- I-engeli phakathi kwemihlathi: Ukuncipha kwe-engeli kunganciphisa ukubumbana kwedwala, amandla okuba nomthelela.

- Isivinini sokusebenza: Ukwehluka kwejubane kungathinta umthamo, ngemiphumela ehlukile ngesivinini esinensayo nesiphezulu.

- Isimo sobuso bomhlathi: Ukugqoka kanye nesimo sobuso bomhlathi kungathonya ukusebenza kahle kokuchotshozwa.

- I-amplitude yokunyakaza kwemihlathi: Ama-amplitudes amakhulu angaholela ekwandeni okusheshayo kwe-theoretical tonnage, okuthinta ukuphuma kwangempela.

- Ukuqina komhlathi: Ukwenyuka kokuqina kunganciphisa ukuhlala kwendawo yokufuduka, kube nomthelela umthamo.

Isilinganiso sokunciphisa

Isilinganiso sokunciphisa sikala ukuthi i-crusher yomhlathi inciphisa kangakanani usayizi wento yokufaka. Lesi silinganiso sibalulekile ekuqondeni ukusebenza kahle kwenqubo yokuchotshozwa. Ama-crusher emihlathi asebenza kahle kakhulu ngokuvamile azuza aisilinganiso sokunciphisa sisuka ku-6:1 siye ku-8:1kuma-crushers ayisisekelo, 3:1 kuya ku-5:1 kuma-crushers esibili, kanye no-2:1 kuya ku-3:1 kuma-crushers emfundo ephakeme.

Isilinganiso sokunciphisa sithonya kakhulu ukusebenza kahle kwama-crusher emihlathini ngokunquma usayizi wento ephumayo kanye namandla okukhiqiza. Ikamelo eliklinyiwe lithuthukisa amandla okukhiqiza futhi liqinisekise usayizi wezinhlayiyana ezifanayo. Ngokuphambene, i-non-choke chamber ingaholela ekunciphiseni ukusebenza kahle kanye nokuma kwezinhlayiyana ezimbi.

- Ikamelo eliklinyiwe likhulisa umthamo wokukhiqizafuthi ikhiqiza izinhlayiya eziphukile ngokufanayo.

- Ikamelo elingaxutshwe linganciphisa ukusebenza kahle futhi libe nomthelela omubi ukuma kwezinhlayiyana.

Ama-crusher emihlathini yokuncelisa kubalulekileukwandisa umthamo wokukhiqizakanye nokuqinisekisa ukuphuka kwezinhlayiyana ezifanayo. Ngokuphambene, ukuncelisa kancane kungaholela ezinhlawulweni ezimbalwa kodwa kuthinte kabi ukwakheka kwezinhlayiyana namandla okukhipha, ekugcineni kuvimbe ukusebenza kahle.

Ukusebenza Kwamandla

Ukusebenza kahle kwamandla kuyimethrikhi yokusebenza ebalulekile emishinini yokugaya imihlathi. Intuthuko yesimanje igxile ekwandiseni ukusetshenziswa kwamandla ngenkathi kugcinwa ukusebenza okuphezulu. Izindlela ezintsha eziqanjiwe zihlanganisa:

- Amasistimu okushayela ahlanganisiwe athuthukisa ukusetshenziswa kwamandla.

- Amapharamitha wokuchoboza alungisekayo anciphisa ukusetshenziswa kwamandla.

- Ukugxila ekuzinzeni emisebenzini yezimayini.

Isibonelo, ama-hybrid crusher e-RM Group athola ukwehla ngo-25% ezindlekweni zikaphethiloli uma kuqhathaniswa namamodeli avamile. Ukonga uphethiloli kungafinyelela ku-50% uma kuhlanganiswe nezikrini eziyingxube.

Intuthuko yakamuva ihlanganisa:

- Izilungiselelo ze-Hydraulic wedge zokulungisa kalula.

- Izinjini eziyinhloko ezisebenza kahle kakhulu.

- Izici ezithuthukisiwe zokuphepha nokusebenza.

Ama-crushers esimanje asebenza kahle kakhulu, njenge-C6X, aklanyelwe ukuthuthukisa ukusetshenziswa kwamandla. Ukwakhiwa okusha kuholela ekusebenzeni okuthuthukisiwe ekucubunguleni okuhlanganisiwe.

Nali ithebula eliqhathanisa amanani okusetshenziswa kwamandla phakathi kwamamodeli adumile e-jaw crusher:

| Amandla Acindezelayo (MPa) | Ukusetshenziswa kwamandla (Isihlobo) |

|---|---|

| 28 | 1 |

| 90 | 4 |

Lezi ntuthuko zinomthelelaizinyawo ze-carbon ezincishisiwefuthi ihambisane nokuqinisa imithethonqubo yokusimama embonini.

Ukufaneleka Isicelo Semihlathi Crusher Machines

Imishini yokugaya imihlathi ihamba phambilikuzinhlelo zokusebenza ezahlukahlukene ngenxa yokuguquguquka nokusebenza kahle kwazo. Ukuqonda izinhlobo zezinto abazicubungulayo, izinhlelo zabo zokusebenza eziqondene nomkhakha othile, kanye nokukala nokuvumelana nezimo kungasiza abasebenzisi benze izinqumo ezinolwazi.

Izinhlobo Zezinto Ezicutshungulwayo

Ama-crusher emihlathi aphatha izinhlobonhlobo zezinto, azenze zifanele izimboni ezahlukene. Ngokwemibiko yemboni, izinto ezicutshungulwa kakhulu zihlanganisa:

| Umkhakha | Izinto Ezisetshenziswa Ngokujwayelekile | Ukwabelana Kwemakethe (%) |

|---|---|---|

| Izimayini | Insimbi, amalahle, ithusi, izinto ezinegolide | 68 |

| Ukwakha | Ama-aggregates, amatshe, imfucuza yokubhidliza | 22 |

Iukusebenza kwama-crusher emihlathinikuyahlukahluka kuye ngobulukhuni bento. Isibonelo, izinto eziqinile njenge-granite (ubunzima be-Mohs obungu-7) zidinga amandla engeziwe ukuze zichotshozwe. Lokhu kuholela ekuphumeni okuphansi uma kuqhathaniswa nezinto ezithambile, njengokhonkolo (ukuqina kwe-Mohs okungu-5). Nansi eminye imininingwane ngobulukhuni bezinto ezibonakalayo:

- Izinto eziqinile zidinga amandla engeziwe, okuholela ekuphumeni okuphansi.

- I-granite echotshozayo ingase ikhiphe cisheamathani ayi-10 ngehora (TPH).

- Izinto ezithambile ezifana nokhonkolo zingafinyelela cishe ku-50 TPH ngaphansi kwezimo ezifanayo.

- Ukuqonda isikali sokuqina kwe-Mohs kubalulekile ekulinganiseni okuphumayo kanye nokuthuthukisa amapharamitha okusebenza.

Izicelo Eziqondene Nemboni

Imishini yokugaya imihlathi isebenzela izimboni ezahlukahlukene, ngayinye inezidingo ezihlukile. Naziizicelo eziyinhloko:

- Imboni Yezimayini: Izigayi zemihlathi zichoboza amatshe amakhulu abe yizicucu ezincane, zicubungula insimbi njengensimbi, ithusi, igolide, nesiliva.

- Imboni Yezinkwali: Bachoboza amatshe, ukhonkolo netiyela uma kwenziwa imisebenzi yokwakha.

- Imboni Yezokwakha: Okuvame ukusetshenziselwa ukuvuselela izinto ezifana nokhonkolo kanye netiyela ekwakheni umgwaqo namaphrojekthi wokwakha.

- Imboni Yokugaywa kabusha: Isebenza kahle ekuchobozeni izinto ezihlukahlukene, okuhlanganisa ingilazi, ipulasitiki, insimbi, nephepha, ikakhulukazi ekugayeni kabusha izinto ezinzima ezifana nemfucuza ye-elekthronikhi.

Izimboni ezahlukene zinezinqumo ezithileizidingo zohlelo lokusebenza. Ithebula elilandelayo lifinyeza lezi zidingo:

| Imboni | Izidingo Zohlelo | Imisebenzi Esemqoka |

|---|---|---|

| Izimayini | Ukuchotshozwa okuyinhloko kwezinto eziqinile neziqhumayo, kunciphisa usayizi we-ore ukuze kucutshungulwe | Ukukhishwa kwe-ore, ukuphatha impahla, ukukhiqizwa okuhlanganisiwe, amasampula omhlaba, ukuphepha kanye nokukhiqiza |

| Ukwakha | Ukugxotshwa kukakhonkolo, izitini, amatshe, nezinye izinto zokwakha ingqalasizinda | Ukubhidliza, ukwakhiwa komgwaqo, umsebenzi wesisekelo, ukugaywa kabusha, ukususwa kwezindawo, ukuphatha izinto |

| Ukugaywa kabusha | Ukuchotshozwa nokunciphisa izinto ezifana nokhonkolo kanye netiyela zibe amafomu angasetshenziswa kabusha | Imisebenzi yokuvuselela kabusha, ukunciphisa imfucuza, ukongiwa kwezinsiza |

I-Scalability kanye Nokuvumelana nezimo

Ukuqina nokuguquguquka yizici ezibalulekile zemishini yokugaya imihlathi. Bazivumelanisa nobukhulu obuhlukahlukene bokusebenza kanye nezidingo zephrojekthi. Ama-crusher emihlathini amaphakathi ngokuvamile anamandla asukela ku-200 kuya ku-500 tph, okubenza bafaneleke izinhlelo zokusebenza ezifana nokumba inkwali nokugaywa kabusha. Ama-crusher amakhulu emihlathi angadlula u-500 tph, amanye amamodeli acutshungulwa kufika ku-1,500 tph, alungele izinhlelo zokusebenza ezinzima. Izinto ezithonya umthamo zihlanganisa:

- Usayizi we-crusher

- Usayizi wokuphakelayo

- Izici zezinto ezibonakalayo

- Imingcele yokusebenza

- Isivinini sokusebenza

- Umswakama obalulekile

Izici zokuguquguquka zithuthukisa ukuguquguquka kwezidingo zephrojekthi. Isibonelo, ukuvuleka kokukhishwa okulungisekayo kuvumela ukulawula usayizi wokuphumayo. Leli khono livumela ukukhiqizwa kwakho kokubili izingcezu ezimahhadla kanye nembudumbudu kakhudlwana. Nasi isifinyezo sezici zokuvumelana nezimo:

| Isici | Incazelo |

|---|---|

| Ukuvumelana nezimo kusayizi wokukhiphayo | Isethingi eseceleni evaliwe (CSS) ingalungiswa ukuze kushintshwe usayizi wokukhiphayo ngezidingo ezahlukahlukene zokuchotshozwa. |

| Ukuguquguquka | Ifanele imisebenzi esukela ekubhidlizeni amatshe amakhulu kuya ekukhiqizeni amatshe agaywe kahle. |

Ama-crusher emihlathi aziwa ngokusebenza kahle kwawo kanye nokuvumelana nezimo, okuwenza abe yinketho ekhethwayo ezinhlelweni ezahlukahlukene zezimboni ngenxa yekhono lawo lokuhlangabezana nezidingo zephrojekthi eziguqukayo.

Ukucatshangelwa Kwesondlo Kwemishini Yokugaya Emihlathini

Ukugcina imishini yokugaya imihlathikubalulekile ekuqinisekiseni ukuphila isikhathi eside nokusebenza kwazo. Izinqubo zokunakekelwa okufanele zinganciphisa kakhulu isikhathi sokuphumula futhi zithuthukise ukukhiqiza.

Ukunethezeka Kwesondlo

Ukulungiswa kalula kunomthelela ngqo ezindlekweni eziphelele zobunikazi bezishicileli zemihlathi. Ukunakekelwa njalo kusiza ukuvimbela ukulungisa okubizayo futhi kugcina imishini isebenza kahle. Abasebenzisi bavame ukubhekana nezinselele, ezifana:

- Umsindo ongajwayelekile ngesikhathi sokusebenza, ekhombisa izingxenye ezixegayo noma izingxenye ezigugile.

- Ukunciphisa umthamo wokuchoboza, okuholela ekwehleni kokukhiqiza.

- Ukudlidliza okweqile kuthinta ukuzinza futhi kubangele ukuguga ngaphambi kwesikhathi kwezingxenye.

Izinqubo zokunakekela ezisebenzayo zinganciphisa lezi zinkinga. Abasebenzisi kufanele babeke phambili ukufinyelela okulula ezingxenyeni zangaphakathi. Ucwaningo lubonisa lokhokuze kufike ku-40% wesikhathi sokulungiswaingasetshenziselwa ukuqaqa nokuhlanganisa kabusha. Ukwenza lula le nqubo kungaholela ekongeni isikhathi esibalulekile.

Ukutholakala Kwezingxenye Ezisele

Iukutholakala kwezingxenye eziselekungenye into ebalulekile ekugcineni ama-crusher emihlathini. Ukufinyelela okusheshayo ezingxenyeni ezishintshayo kuqinisekisa ukuphumula okuncane. Nasi isifinyezo sokutholakala kwezingxenye ezisele zemikhiqizo emikhulu:

| Ibhrendi | Ukutholakala Kwezingxenye Ezisele |

|---|---|

| Terex | Izingxenye ezintsha zokufakela i-Jaw Crusher Wear ziyatholakala |

| Sandvik | Izingxenye ezintsha zokufakela i-Jaw Crusher Wear ziyatholakala |

| Isikrini samandla | Izingxenye ezintsha zokufakela i-Jaw Crusher Wear ziyatholakala |

| Mdlwembe | Izingxenye ezintsha zokufakela i-Jaw Crusher Wear ziyatholakala |

| I-Extec | Izingxenye ezintsha zokufakela i-Jaw Crusher Wear ziyatholakala |

| Finlay | Izingxenye ezintsha zokufakela i-Jaw Crusher Wear ziyatholakala |

Imikhiqizo efana ne-GTEK Mining iphinde inikeze ngezingxenye ezakhelwe impilo ende yesevisi, iqinisekisa ukuthi opharetha bangathola izingxenye zokugqokwa kwansuku zonke noma ukuphuka okungalindelekile.

Izindleko Zokulungisa

Izindleko zokunakekela zingahluka kakhulukubo bonke abakhiqizi abahlukene kanye nezinhlelo zokusebenza. Nasi isiqhathaniso sezindleko zokulungisa ezijwayelekile ezisuselwe ohlotsheni lohlelo lokusebenza:

| Uhlobo Lohlelo Lokusebenza | Ibanga Lentengo Lokuthenga Elijwayelekile | Izindleko Zokulungisa |

|---|---|---|

| Izimayini kanye Nemisebenzi Enzima | $$$$ | Kuphakathi kuya Ekuphakameni |

| Ukukhiqiza Okuhlanganisiwe | $$$ | Kuphakathi |

| Ukwakhiwa Kwezinga Elincane | $$ | Phansi |

Izindleko zonyaka zokulungisa ama-crusher emihlathini ngokuvamile zisukela ku-$15,000 kuya ku-$25,000 iyunithi ngayinye. Lezi zindleko zincike ekusetshenzisweni kokuqina nezimo zemvelo. Ngokuqonda lezi zici, opharetha bangenza izinqumo ezinolwazi ezithuthukisa ukusebenza kahle nokuthembeka kwemishini yabo yokugawula imihlathi.

Ukusekelwa Kwangemuva Kokuthengisa Kwemishini Ye-Jaw Crusher

Ngemva kokuthenga i-crusher yomhlathi,ukusekelwa ngemuva kokuthengisa kuba okubalulekileukuze kukhuliswe inani layo. Izinhlelo eziqinile zokusekela zingathuthukisa kakhulu ukusebenza kahle futhi ziqinisekise ukwaneliseka kwesikhathi eside.

Iwaranti kanye Nezivumelwano Zesevisi

Abakhiqizi abahamba phambili be-crusher emihlathini ngokuvamile bayanikezelaiwaranti eqinile nezivumelwano zesevisi. Lezi zivumelwano zinikeza ukuthula kwengqondo futhi zivikele ukutshalwa kwezimali. Nasi isifinyezo semigomo yesiqinisekiso esijwayelekile:

| Isici | Imininingwane |

|---|---|

| Isikhathi sewaranti | Iminyaka emibili kusukela ngosuku lokuqala kokugunyazwa. |

| Ukuhlanganisa | Izesekeli ezintsha zokushintshwa nokulungiswa uma kungewona umonakalo owenziwe umuntu. |

| Ukusekela kwezobuchwepheshe | Usekelo lobuchwepheshe lwamahhala lokuphila lunikeziwe. |

| Isikhathi sokuphendula | Izinkinga zekhasimende ezisingathwe phakathi kwamahora angu-24, zixazululwe phakathi namahora angu-72. |

Iziqinisekiso ezinjalo zibonisa ukuzethemba kwabakhiqizi emikhiqizweni yabo. Baphinde baqinisekise ukuthi amakhasimende athola usizo ngesikhathi lapho ludingeka.

Ukutholakala Kosekelo Lwekhasimende

Ukutholakala kosekelo lwekhasimende kungesinye isici esibalulekile. Abakhiqizi abaphezulu bahlinzeka ngamaqembu asekelayo azinikele ukusiza abasebenzisi. Izimpendulo ezisheshayo zemibuzo zinganciphisa isikhathi sokuphumula futhi zithuthukise ukukhiqiza. Izinkampani eziningi zinikeza iziteshi eziningi zosekelo, okuhlanganisa ucingo, i-imeyili, nengxoxo ebukhoma. Lokhu kufinyeleleka kuqinisekisa ukuthi opharetha bangakwazi ukuxazulula izinkinga ngendlela efanele, okubavumela ukuthi bagxile emisebenzini yabo eyinhloko.

Ukuqeqeshwa Nezinsiza

Izinhlelo zokuqeqesha ezinikezwa abakhiqizi zidlala indima ebalulekile ekusetshenzisweni ngempumelelo kwemishini yokugaya imihlathi.Abaqhubi abaqeqeshwe kahle bangaphendula izinselele ngempumelelo. Nazi ezinye izinzuzo ezibalulekile zalezi zinhlelo zokuqeqesha:

- Ukuqeqeshwa komsebenzisi kubalulekile ekusetshenzisweni kwemishini ephephile.

- Izifundo zokuvuselela njalo zigcina opharetha benolwazi ngezobuchwepheshe nezinqubo zokuphepha.

- Ukuqeqeshwa kwenzelwe umshini othile nendawo yomsebenzi.

Lezi zinhlelo zinciphisa amaphutha futhi zithuthukise ukuphepha kwendawo yokusebenza. Baphinde bathuthukise impilo ende yemishini ngokuqinisekisa ukusetshenziswa okufanele. Ama-opharetha afunda ukuxazulula izinkinga eziyisisekelo kusayithi, bathole impendulo esheshayo esiza ukuthuthukisa ukusebenza komshini. Ukutshala imali ekuqeqesheni akukhulisi umkhiqizo kuphela kodwa futhi kukhuthaza isiko lokuphepha nokusebenza kahle.

Kafushane, ukukhetha imishini yokugaya imihlathi efanele kuhilela ukuqonda izici ezimbalwa ezibalulekile. Izici ezibalulekile zihlanganisaamandla okuchoboza, usayizi wokuphakelayo, ukulungiswa kokuphumayo, nokuphatheka. Lezi zici zithinta kakhulu ukusebenza kahle kanye nokukhiqiza kukonke.

Cabangela lezi zici lapho uthenga:

- Ikhono lokuchoboza: Qinisekisa ukuthi ihambisana nezinjongo zokukhiqiza.

- Usayizi Wokudla: Qondanisa umshini nosayizi omkhulu wezinto zakho.

- Ukuguquguquka: Bheka izilungiselelo ezivumela ukulawula usayizi wokuphumayo.

- Ukuphatheka: Khetha ngokusekelwe kuzidingo zesayithi kanye nokunethezeka.

Ngokubeka phambili lezi zici, opharetha bangenza izinqumo ezinolwazi ezihlangabezana nezidingo zabo ezithile.Izifundo zecala eziyimpumelelo, njengephrojekthi yezimayini yaseNingizimu Afrika kanye nemboni yegwadle yase-Uganda, ibonisa izinzuzo zokukhetha imishini ngokusekelwe kulezi zindlela.

FAQ

Uyini umsebenzi oyinhloko womshini wokugaya imihlathi?

Imishini yokugaya imihlathi ngokuyinhloko igxoba amatshe amakhulu abe yizicucu ezincane, ezilawulekayo. Bahamba phambili ekubhidlizeni izinto eziqinile ezifana negwadle, i-limestone, nensimbi, okubenza babaluleke ezimbonini zezimayini nezokwakha.

Ngikhetha kanjani i-crusher yomhlathi efanele ngezidingo zami?

Cabangela izici ezifana nomthamo wokuchoboza, usayizi wokuphakelayo, nohlobo lwezinto ezibonakalayo. Hlola izidingo zakho zohlelo lokusebenza bese ukhetha imodeli ehambisana nemigomo yakho yokukhiqiza kanye nezimo zokusebenza.

Yiziphi izindlela zokunakekela okufanele ngizilandele kuma-crusher emihlathini?

Hlola njalo izingxenye ukuthi azigugile, qinisekisa ukugcotshwa okufanele, futhi uhlanze umshini ukuze uvimbele ukunqwabelana kwemfucumfucu. Hlela ukunakekelwa okujwayelekile ukuze uxazulule izinkinga ezingase zibe khona ngaphambi kokuthi zidlondlobale.

Ingabe izingxenye ezisele zitholakala kalula kuma-crusher emihlathini?

Yebo, abakhiqizi abaningi abahloniphekile bahlinzeka ngezingxenye eziningi ezisele. Ukufinyelela okusheshayo kulezi zingxenye kunciphisa isikhathi sokuphumula futhi kuqinisekisa ukusebenza kahle, okuthuthukisa ukukhiqiza okuphelele.

Ngingakuthuthukisa kanjani ukusebenza kahle kwamandla kwe-crusher yomhlathi wami?

Lungiselela amapharamitha okusebenza, njengokulungisa isivinini sokuchotshozwa nezinga lokuphakelayo. Ukugcinwa okuvamile kanye nokusebenzisa amamodeli asebenza kahle kakhulu kunganciphisa kakhulu ukusetshenziswa kwamandla kanye nezindleko zokusebenza.

Isikhathi sokuthumela: Oct-15-2025